Today, speed and accuracy are critical in product development. A company is under growing pressure to get to market sooner, but at the same time, it must drastically cut down design errors, development costs, and validation risks.

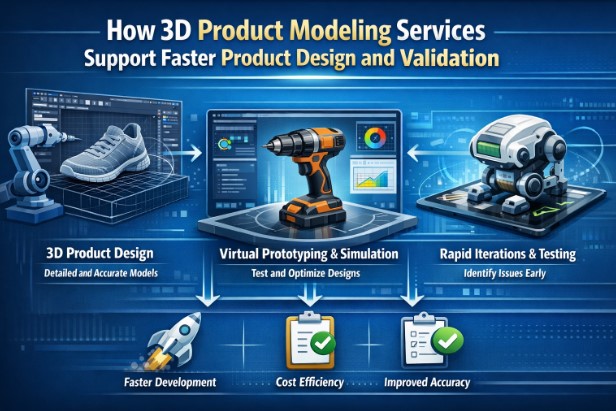

Traditional design processes that are heavily reliant on physical prototypes and their manual revisions slow down innovative processes and raise uncertainty. That is a spot where 3D product modeling services transform the ability of teams to design, test, and validate products more efficiently before committing to manufacturing.

By replacing guesswork with precision and iteration with simulation, digital modeling has become the cornerstone for state-of-the-art product development.

Acceleration of the Early Design Phase

Most decisions occur at early stages of product design, and this is also where changes are the least expensive to make. However, without strong visualization, the teams often struggle to align on form, dimensions, and functionality.

3D product modeling enables designers and engineers to:

- Accurately visualise concepts in three dimensions

- Rapidly explore variations in design

- Identify design flaws early on

Teams work with detailed digital representations that support real-world proportions and constraints rather than being confined to 2D sketches or rough mockups. This clarity greatly reduces back-and-forth during concept approval.

Faster Iteration Without Physical Prototypes

Most traditional product development relies on multiple physical prototypes to evaluate form and fit. Every iteration represents time, materials, and coordination of the overall process.

Digital models enable speedy iterations. They allow teams to:

- Change geometry in an instant

- Test alternative designs without rebuilding prototypes

- Compare versions side by side

3D product modeling services help design teams validate their ideas digitally, even before any physical samples are produced.

Improving Cross-Team Collaboration

Product design rarely occurs in a vacuum. For a product to really meet technical, functional, and market needs, there needs to be synergy among designers, engineers, and manufacturers, among others.

3D models offer a common frame of reference that enables these teams to do the following:

- Clearly Convey Design Intent

- Identify conflicts between aesthetics and engineering

- Align expectations among departments

There are fewer misunderstandings and faster decision-making with greater certainty when everyone is working from the same digital model.

Early Detection of Design and Engineering Issues

One of the largest advantages of digital modeling is being able to identify issues up front in manufacturing. In fact, design flaws that are left until later stages are expensive and disruptive.

With detailed modeling, teams can:

- Detect interference or assembly problems

- Dimensional and tolerance validation

- Ensure components fit together properly

Finding these problems early avoids expensive redesigns and delays later in the development cycle.

Virtual Testing and Validation Support

The 3D model allows virtual testing and analysis, besides visualization. Of course, physical testing will be required to some extent, but the proportion of dependency on repeated physical trials is considerably reduced with digital validation.

Digital models support:

- Structural and Stress Analysis

- Fit and clearance checks

- Simulation of real-world usage scenarios

These virtual validations enable quicker, better-informed decisions by teams with greater confidence before committing to tooling or production.

Enhancing Design Accuracy for Manufacturing

Manufacturability is a very important consideration in product design. Designs that look good conceptually may be difficult or expensive to produce if manufacturing constraints are not considered early.

Precise 3D modeling involves:

- Designs follow guidelines on manufacturing.

- Materials and tolerances are correctly defined.

- Early detection of possible production issues.

By integrating manufacturing considerations in the design phase, teams reduce friction between design and production.

Faster Approvals from Stakeholders and Clients

Stakeholders and clients often find it hard to perceive the final product from the technical drawings. Misconceptions result in delays or late-stage changes.

High-quality 3D Models:

Provide Realistic Visual Previews.

Help non-technical stakeholders understand the design.

Enable faster feedback and approvals.

Cycles of approval are smoother and more conclusive once the decision-makers can see what the end will look like.

Reduce Development Costs and Risk

Every design change made late in the process is more costly and risky. By front-loading validation and iteration into the digital phase, companies can drastically reduce expenses downstream.

Some key cost-saving benefits:

- Fewer physical prototypes

- Less rework in production

- Reduced risk of product recalls or failure

This reduction of risk is one of the major reasons why most companies now rely on professional 3D modeling services as their core development strategy.

Faster Time-to-Market Enabled

By streamlining design and validation, digital modeling:

- Shortens Development Timelines

- Reduces bottlenecks between stages

- Enables parallel workflows between teams

This efficiency allows products to get to market faster with no quality compromises.

Supporting innovation and design exploration.

When iteration is cheap and fast, teams will take more risks. Digital modelling eliminates many of the barriers that traditionally have limited creative exploration.

Design teams can:

- Test bold ideas without high risk.

- Explore unconventional forms or mechanisms.

- Improve the products with real-time input.

This freedom enables creativity while exerting control over feasibility and performance.

With growing product portfolios, consistency and efficiency in managing designs become increasingly hard; digital modeling provides a foundation on which scale and growth can be efficiently achieved.

Conclusion

Speed and accuracy are no longer mutually exclusive in product development today. 3D product modeling services play an integral role in helping to accelerate the design cycle while minimizing risk by way of rapid iteration, early validation, and clear collaboration. Digital modeling from conceptualization to the start of manufacturing empowers teams to make informed, quicker decisions toward higher quality products with less time-to-market.