In an increasingly digital world, the invisible workhorses powering our devices, from smartphones to supercomputers, are tiny, intricate components built on semiconductor wafers. These seemingly simple discs are the foundation of modern technology, enabling everything from artificial intelligence to medical advancements. But what exactly are these crucial components, and why are they so vital? This article delves into ten essential facts about semiconductor wafers, offering a comprehensive look at their significance, manufacturing, and future.

1. The Foundation of All Electronics

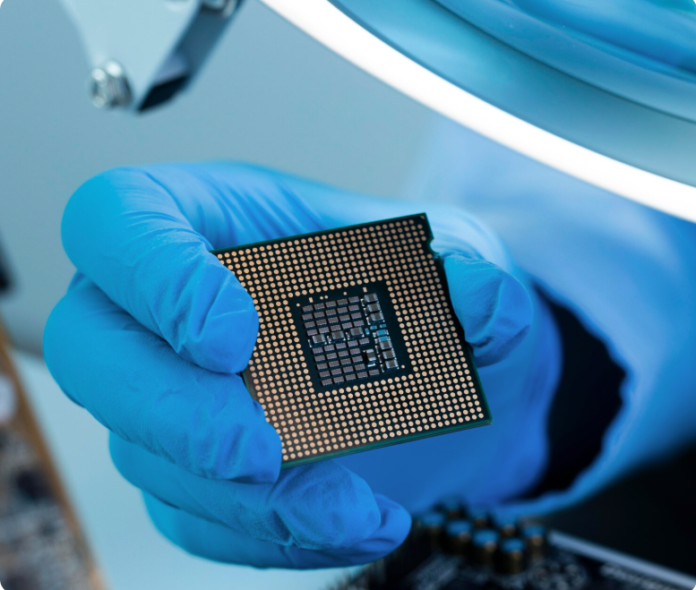

At its core, a semiconductor wafer is a thin slice of semiconductor material, typically crystalline silicon, used for the fabrication of integrated circuits (ICs). Think of it as the blank canvas upon which the intricate circuitry of a microchip is painted. Without these fundamental discs, the digital revolution as we know it simply wouldn’t exist. Every microprocessor, memory chip, and sensor relies on the precise engineering that begins with the creation of these wafers.

2. Silicon Reigns Supreme (Mostly)

While other materials like gallium arsenide (GaAs) and silicon carbide (SiC) are used for specialized applications (e.g., high-frequency devices or power electronics), silicon remains the dominant material for semiconductor wafers. Its abundance, cost-effectiveness, and excellent electrical properties make it the material of choice for the vast majority of integrated circuits. The process of refining sand (silicon dioxide) into ultra-pure, single-crystal silicon is a marvel of materials science.

3. The Incredible Purity Requirement

The performance of an integrated circuit is directly tied to the purity of the semiconductor wafer. Impurities, even at parts-per-billion levels, can disrupt the delicate electrical properties of the silicon, leading to defects and device failures. This necessitates an incredibly stringent manufacturing process, often conducted in cleanrooms that are hundreds to thousands of times cleaner than a typical operating room. Maintaining this level of purity throughout the entire production chain is a monumental task.

4. Size Matters: From Small to Super-Sized

Semiconductor wafers come in various diameters, typically measured in millimeters (mm) or inches. Common sizes include 200mm (8-inch) and 300mm (12-inch). The trend has always been towards larger wafers because more chips can be fabricated on a single wafer, leading to economies of scale and lower per-chip costs. The industry continually invests in developing technology for even larger wafers, though the challenges in maintaining uniformity and yield increase significantly with size.

5. The Journey from Sand to Chip: A Complex Process

The creation of a finished integrated circuit from a raw semiconductor wafer is a multi-stage, highly complex process. It involves hundreds of steps, including photolithography (etching patterns using light), doping (introducing impurities to alter electrical properties), deposition (adding thin layers of material), and etching (removing unwanted material). Each step requires extreme precision and control, with tolerances often measured in nanometers. This intricate dance of chemistry and physics transforms a plain disc into a powerhouse of computation.

6. The Role of Epitaxial Layers

For many advanced semiconductor devices, a pure silicon wafer isn’t enough. An epitaxial layer (or epi-layer) is often grown on top of the base wafer. This layer is a thin, precisely controlled crystal film that can have different doping concentrations or even different materials, optimizing the electrical characteristics of the device. This allows for greater flexibility in device design and performance, especially for high-speed or high-power applications.

7. Defects are the Enemy of Yield

In semiconductor manufacturing, yield refers to the percentage of functional chips produced from a single wafer. Defects, whether microscopic particles, crystal imperfections, or processing errors, can render entire sections of a wafer unusable. Manufacturers employ sophisticated inspection techniques and statistical process control to minimize defects and maximize yield, as even a small improvement can translate into significant cost savings.

8. The Economic Impact is Immense

The market for semiconductor wafers and the chips they produce is gargantuan, underpinning a global industry worth trillions of dollars. Countries and regions heavily invest in wafer fabrication facilities (fabs) due to their strategic importance and the high-paying jobs they create. The geopolitics of semiconductor manufacturing, particularly the production of advanced semiconductor wafers, is a major topic of discussion among world leaders.

9. Next-Generation Materials and Technologies

While silicon dominates, research and development continue into alternative materials and advanced wafer processing techniques. Silicon carbide (SiC) and gallium nitride (GaN) are gaining traction for power electronics and high-frequency applications due to their superior performance at high temperatures and voltages. Furthermore, advancements in 3D stacking of chips directly on wafers are pushing the boundaries of integration and performance, promising even more powerful and compact devices.

10. The Future is Built on Wafers

As we move towards an era of ubiquitous AI, autonomous vehicles, 5G connectivity, and the Internet of Things, the demand for more advanced and efficient integrated circuits will only grow. This, in turn, will drive continued innovation in the production and quality of semiconductor wafers. The challenges of shrinking transistor sizes, managing heat, and improving energy efficiency all begin with the fundamental properties and flawless manufacturing of these critical components. The future of technology truly rests on the shoulders of these unassuming discs.

—

Author Bio:

The author is a seasoned technology writer with over a decade of experience covering advancements in materials science, electronics manufacturing, and artificial intelligence. With a passion for demystifying complex technical topics, their work aims to educate and inform a broad audience about the foundational elements driving our digital world. Their insights are regularly featured in industry publications and online technology portals.”